Sugar Production Line

One of the services in Heatmanco company is designing and setting up a sugar production line. Below are the details of the sugar production line.

1- Planting, cultivating and harvesting beets

Healthy and ripe beets are ready to be harvested and usually before being transported to the factory, their heads and tails are cut off, and it is better to be free of foreign materials as much as possible.

2- Delivery of beets to the factory

The beets are usually transported to the factory by truck and after weighing the truck with its cargo in the weighing area, the truck goes to the grader and samples are taken from the beets with a special device to measure the grade of the samples. The price of beetroot is paid based on the net weight of beetroot and its sugar percentage, as well as according to the percentage of weight loss related to soil, mud and other impurities associated with beetroot.

3- Emptying beets and storing them in silos

After emptying the contents of the truck by the emptying device in the silo, the beets should be kept in the silo until consumption. Long-term storage of beets in silos should be avoided, because beets in silos face the phenomenon of weight loss and sugar waste due to respiration and microbial spoilage.

4- Transfer of beets to the place of processing

Water flow is often used to transport beets from the silo to the place of processing. At the same time, on the conveyor ,operations such as stone removal are also carried out.

5- Washing beets

Washing of beets is done using water and in semi-cylindrical washing machines in which rotating arms and grinding of beets are done together.

6- Preparation of beet slices

In order to facilitate the extraction of sugar from beet, it is necessary to cut it into thin strands. This work is done in a device known as Slicer. The size, shape and thickness of slices have a great effect on the extraction efficiency. During production, samples are taken and their sugar percentage is measured during a test called digestion. The slices are weighed with special scales before entering the next stage. Therefore, by having their weight and percentage of sugar, the amount of sugar entered into the process can be determined.

7- Sugar extraction through (Extraction)

This stage is also called syrup extraction, extraction or diffusion. The process of extraction is also done from the filter in a diffusion device or diffuser using the property of diffusion and osmotic pressure, which is related to the concentration difference inside and outside the cells of the filter. Heat and stirring help to release the sugar better. Usually, in diffusion, hot water and the pulp move in two opposite directions, and sugary substances are gradually extracted from the pulp, and finally raw syrup comes out from one side of the device and pulp from the other side. In fact, scum is a pulp in which the sugar in it has been taken as much as possible. Of course, usually a small amount of sugar remains in it, which is considered part of the factory’s sugar waste.

8- Drying the scum

The slurry coming out of the diffuser is under pressure, and a large amount of water containing sugars is separated and returned to the diffuser. The resulting slurry is called pressed slurry, which can be sold directly and consumed it reaches the livestock or it is transferred to the drier section and turns into dry dung there which is used as animal feed. To increase the nutritional value of dung for livestock, molasses is often added to it.

9- Raw Juice Purification

The raw syrup coming out of the diffuser has a gray to green color and has a lot of impurities, so it must be filtered. In the most common method of purifying raw syrup, lime juice and carbonic gas are used to separate impurities. In this method, there are the following steps.

10- Concentration of syrup or evaporation (juice evaporation)

Thin syrup has a low concentration and the percentage of solids is about 12-13%, so it should be thickened. This work is done in condensing devices or evaporators using steam. In order to reduce the hydrolysis of sugar and change the color of the syrup under the influence of high heat, as well as to save energy consumption, syrup thickening is done in multi-stage thickening systems under vacuum at a lower temperature. In the end, Brix of thick juice, for example, reaches about 60%.

11- Cooking or crystallization (Crystallization)

The purpose of this step is to thicken the syrup to a greater extent so that sucrose can be separated from it in the form of crystalline sugar. The cooking process is done in several stages, for example three stages. In the first stage or cooking base, thick syrup or other solutions containing sugar are introduced in vacuum pans or cooking apparatus and thickened under vacuum until it reaches a supersaturated state. Then, by creating a shock, which is usually done by introducing some sugar powder into the apparatus, the process of seeding or creating the initial nuclei of the crystal is done, then the crystals grow. They become Finally, the contents of cooking pot I, which includes sugar crystals and the waste water around it and is called massecuite 1, are introduced into the cooling tanks from the apparatus and then enter the centrifuge machine to be used Sugar crystals are separated from the effluent due to the centrifugal force and special nets of the mentioned device. In the three-baking systems, which includes baking III, II, and I, in baking I, after the centrifuge stage, white sugar and baking waste I are obtained. The effluent from the cooking centrifuge I usually goes to cooking II, and after the cooking and crystallization steps, muscovite II is finally obtained, which is transferred to the cooler and then centrifuged, and the result is cooking sugar II (yellow sugar) and wastewater. Baking is II. The effluent of baking II usually goes to baking III, which after the cooking steps, muscovit III is obtained It turns out that there is a mixture of sugar crystals in the dark effluent. Muscovit III enters the cooler from cooking apparatus III and after a while it is centrifuged, which results in cooking sugar III (red sugar) and final cooking effluent (molasses). Although molasses contains about 50% sugar, it is not possible to separate sugar from it by normal crystallization methods, and special methods are used to separate sugar from molasses, although molasses is considered an important product of sugar factories and has many uses. If the purpose of the factory is to produce sugar, the sugar obtained from baking I (white sugar) is transferred to a dryer and after drying and packaging, it is sent to the warehouse or the market, but if the factory is part of the sugar production (candle sugar or granulated sugar) ), the white sugar that comes out of centrifuge I is dissolved in water instead of being dried and clairce is prepared. It is poured and after cooling, centrifugation and drying, sugar is obtained. Yellow sugar obtained from cooking II is usually dissolved in water and is used as chlorine II in the preparation of cooking I, and cooking sugar III (red sugar) usually turns into chlorine III after dissolving in water and is used in cooking II or baking I is used. As we go from baking I to baking III, the color of baking is darker and the amount of impurities in it is higher. In some factories, they mix Chlores II or yellow sugar with thick syrup and prepare standard liquor. This syrup is often used in cooking I.

Grinding mill

The slicing mill with a height of 2.5 (m) (because it provides the necessary pressure for the beet to enter the mill) when the beet is sliced in the mill, it is cut into slices and then enters the RT tape, after weighing (weighing) through the shot It entered the BMA strip and after weighing it was poured into the mixer, inside the mixer, the poured cake was heated between 60-85 degrees Celsius, the membrane of the cake cells swelled and the juice was extracted from it, and the flow inside the mixer was uneven At the end of the mixer, a net is installed, the syrup extracted inside the mixer (raw syrup) is directed to the satration, on the other side of the mixer (in front of the pump), the syrup and the syrup are guided into the tower by means of variable speed pumps. In the upper level of the mixer, another net is installed, the resulting syrup and foam are directed into the tank of the bottom of the boiler, which is returned to the mixer again after the foam is collected again through the pump.

1- The B.M.A Tower Diffuser

Inside the tower, after entering the pulp and syrup, the syrup is returned to the mixer from the bottom of the net and the sides of the nets, the time required for the pulp to be removed from the upper end of the tower by means of double helices (in (time 80-90 minutes) the slag is directed to the presses, from there to the softener and from the softener to the slag water tank next to the tower and then into the roshofer (the temperature inside the roshofer is 70-75 degrees Sanigrad) and from there it is directed into the tower, and since the waste water contains some sugar, in order to have less sugar waste, we use the sulfation route. On the other hand, we have water without hardness, which has been heated to 60-65 degrees Celsius, then from entering into the fiber class tank, it is carried out by the Kola Sear pumps connected to the Kola Sear tank. Its function is that after turning on the sulfur furnace, the resulting gas passes through the garbage collector to The suction net device is mixed with water and directed into the fiber class tank, where an acid or sulfite environment is obtained. There is also an agitator inside the tank that pumps the internal environment (mixed gas and water into one) into the storage tank by the relevant pumps to the tower slab (the necessary height between the inlet of fresh water and waste water is approx. It is 2 meters and it is for this reason that since the waste water contains sugar, in order to extract the existing sugar and prevent sugary waste from the water, we use sulfation, which is called sulfation. Slow 3) extracts sugar.

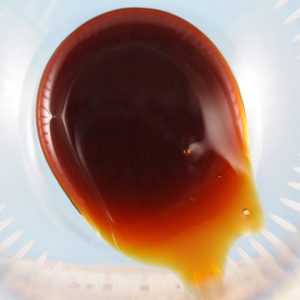

Refinement of raw sherbet (Row) wce Purification

The syrup coming out of the dinoizer device has a green color opposite to gray, one of the reasons for the dark color of the syrup is the enzyme activities that produce the color of dark particles like melanin. %) The pH of raw syrup is often in the range of 5.8-6.5, and the pH of 6.3 can relatively indicate the health of the consumed beet and good performance in the syrup extraction stage. slow. This degree of purity indicates the presence of a large amount of impurities in the syrup, therefore, this degree of purity should be brought to a percentage higher than 90 by applying the purification process as much as possible, so that it is possible to go through the steps of concentration and crystallization in the desired way.

2- Second or main lime or chaulage (Liming, chaulage)

The amount of lime juice consumed in the main liming stage is about 9 to 10 times that of the first stage, and the level of alkalinity, for example, reaches more than 1.5 grams of calcium oxide per hundred cubic centimeters of syrup. For example, at a temperature of 70 degrees Celsius, about 15 minutes, and if the temperature reaches about 85, the time will be reduced to 10 minutes. The main liming device is usually in the form of a vertical cylinder in which a stirrer with long paddles is installed so that the lime syrup enters the device and mixes it well.

First Carbonation

The carbonation device or Carbonator consists of large cylindrical tanks, from the upper part of which limed syrup is introduced and from the lower part, carbon dioxide is blown into the syrup, the injection of carbon dioxide is done through pipes that have holes They have many and they spread the gas in the form of bubbles in the syrup, the device can also have a stirrer. As mentioned in the liming stage The main thing is to try to create free lime in the syrup. In the carbonation stage, by adding carbonic gas to the syrup, the mentioned lime is converted into calcium carbonate, and this substance, which is ready to precipitate, will absorb other impurities and precipitate with itself. The main reaction in the carbonation stage is the creation of calcium carbonate in the syrup. Another goal of this stage is to convert the limes that have become saccharified with sucrose into calcium carbonate and release the sucrose molecules.

Sulfation

To reduce the color of the syrup, you can apply sulfur dioxide to the syrup. For this purpose, you must have a device in which sulfur is burned and converted into sulfur gas. The mentioned device is called sulfur furnace. The obtained gas is injected into the syrup by means of a sulfur gas injection device (sulfitator).

1- Syrup concentration (Evaporation, Concentration)

The syrup obtained after the refining process is called thin juice. For example, this syrup has a percentage of soluble dry matter of about 12-16% and a degree of purity of about 90-93%. Of course, the characteristics of the said syrup are different in different factories, and in advanced industrial countries, due to the application of complementary methods in the purification stage, the syrup is obtained with a higher degree of purity. A little in the thin syrup, before transferring it to the cooking stage, it should be thickened and turned into a thick syrup with a concentration of about 50-70 (usually the concentration is about 60-65). Syrup thickening is done in evaporating or thickening devices or evaporators, and usually the aforementioned process is continuous under vacuum and using steam. Today, single-stage evaporators are not used much in the concentration of dilute syrup, and multiple-effect evaporators are used.

2- Crystallization part

The thick syrup obtained from the thickening stage often has a Brix of about 60-65% and its purity level is almost similar to the purity level of dilute syrup. In the normal working routine of the factories, this syrup is transferred to the cooking stage after being smoothed to produce sugar. In some factories, before transferring the thick syrup, they reduce its color by using decolorization methods, for example, the use of activated carbon, and in some other factories, they turn the thick syrup into standard liqueur and then use it in the crystallization stage.

– Clairce: (Clairce or Remelt Sugar)

The sugar that comes out of baking I or II or III, if it is dissolved again in water and used, is called chlorine. For example, if yellow sugar (cooking sugar II) obtained from the centrifuge of cooking part II is dissolved in water, it will be chlorine II. Chlores II after filtering can be used in the preparation of baking I. Brix is about 60-62% for the preparation of bleaches and dissolving sugar from a mixer equipped with stirring that is a sugar dissolver (refonte or melter). They use Water It is better that the gram used in chlorine production is not hard, so condensed water is often used. But in some cases, instead of condensed water, warm thin syrup is used to dissolve sugar. But for the preparation of Cress I, which is used for making sugar, it is not usual to use thin syrup and they use warm condensed water.

White sugar + water = chlorine I (chlorine I for sugar production)

Yellow sugar + water = chlorine II (chlorine II for cooking I)

Red sugar + water = chlorine III (chlorine III for baking II)

– Cooking coolers or Refrigerants:

They include tanks that are installed under the cooking pots and the contents of the cooking pot are emptied after the cooking (muscovit) is finished. These tanks are equipped with strong stirrers and prepare the muscovit for centrifugation. In some factories, cooking refrigerants I and II, whose role of cooling is less important and they play the role of mixing muscovit, are called cooking mixer or mixer or malaxor, but in the case of cooking III, the role of the above device in cooling muscovit In order to continue the growth of sugar crystals, it is very important, that’s why the device is not a simple mixer, but its mixers are double-walled filaments and by establishing the flow of cold water in their inner wall, they cool the muscovite as much as necessary to increase The supersaturated state of crystal growth in the device continues until the centrifugation stage.

3- Centrifuging

Centrifuge devices are used for centrifugation of baked goods in factories, which can be continuous centrifuge or non-continuous centrifuge for sanitizing while rapidly tending by applying centrifugal force to separate syrup and most of the impurities from the sugar crystals in muscovit. and so on The sugar crystals remain behind the closed strainer. Today, new centrifuge devices are used in the factory, and all operations including entering the muscovit into the centrifuge (loading), adjusting the speed, washing with water, washing with steam, draining the effluent and sugar are completely automatic according to the program given to the device in advance. is done The number of revolutions of the centrifuge is 1800 revolutions per minute. The time interval from entering the muscovit into the centrifuge and starting the rotation of the centrifuge until the end of the work depends on the type and capacity of the centrifuge, but it usually takes about 3 to 4 minutes.

-Drying and drying sugar

- Drying white sugar:

The white sugar that comes out of the cooking centrifuge has about 1-2% moisture, so it should be dried to increase its shelf life. This work is done in sugar drier machines, which are also called granalators, and its types can be named: 1 Rotary Dram Drier, which is a large horizontal cylinder which has a rotational movement and is installed in an inclined manner, after entering the dryer, the white sugar moves forward in the direction of the slope, and in the opposite direction, there is a flow of dry and warm air, which is used in the Abkoh sugar factory. to be

- Turbo-Tray Drier

- Roto-Louver Drier

Sifting sugar

After drying, the sugar is sifted. For this purpose, different types of sieves are used. It is better to have vibrating sieves and they are installed in multiple layers and back to back. In this way, first the big lumps of sugar are separated, and in the next steps, the smaller ones are separated, and finally, the suitable sugar grains are removed from the machine. The separated lumps can be dissolved in water and returned to the sugar production line.

– Sugar Storage

-Sugar is kept in two ways, one is bulk and packaged.

– Sugar packaging:

Sugar is packed for better storage and easier transportation. Among the suitable packages for sugar are plastic bags made of high-density polyethylene (HDPE), which are resistant to moisture penetration to a large extent, and after pouring sugar into it, the lid is closed with heat sealing. will be And then it is marketed.